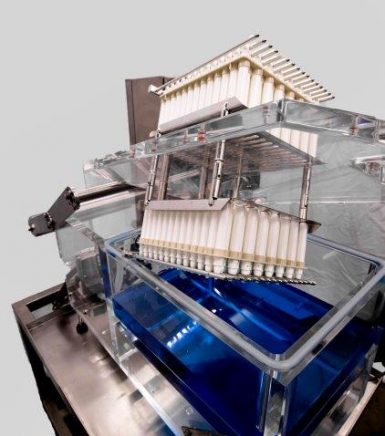

Vacfiller 100

MANUAL FILLING LINE FOR FINE-TIPPED AMPOULES

Applications :

Designed to meet the requirements of filling fine-tipped ampoules, this line was built to obtain the same regular production quality of its higher-volume sisters. This physical packaging machine “produces” while limiting downtime and unproductive time and meets the requirements of pharmaceutical, food science, chemical sectors.

General description :

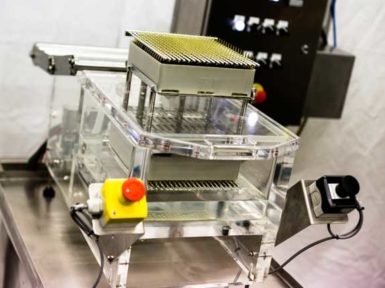

Line composed of two modules which make up the core machine :

-> Filling and sealing

Additional modules:

-> Seal watertightness checking -> washing -> pre-drying -> sterilisation -> racking -> placement into sachets

Compatible with two types of fine-tipped ampoules :

– Flackpull® double-tipped ampoules, bottles or capped ampoules ;

– Fillable volumes from 1 to 30 ml.

Simple to use :

– Rapid learning curve and intuitive ;

– Manual loading and unloading ;

– Automatic filling cycle ;

– Closure by heat-sealing or tying ;

– Rapid change of format -> short preparation times.

Physical machine with a capacity of 75 crystallisers per hour (rate based on tap water).

Uses

- Propane and compressed air (pressure 1 bar).

- 220 volts 50 Hz 16 A and/or 380 volts 50 Hz 20 A.

- Filtered compressed air at constant 6 bars.

- Connection to water cleaning / evacuation system.

- Cold water

- Hot Water

Technical characteristics

- Standard construction compliant with BPF

- Automatically-controlled filling cycle

- Easy and rapid setup – modules marked with an index number

- Auto-controlled lighting and extinguishing cycle of the flame*

- Flame-detection guaranteeing operator security*

- Horizontal safety screen in Securit* glass

- Vacuum pump

- Dimensions: length 4000mm, width 600mm, height 2000mm

- Exterior dimensions of the crystaliser 202X202 mmRapid change of format

*optional